Github link

Project Objectives

The purpose of this project is to design a device that manufactures robotic whisker sensors by drawing polymer plastic filament from an oven. It must be able to inspect the diameter of the whisker and adjust the draw speed accordingly to match a specific geometric profile. This process must be quick and repeatable.

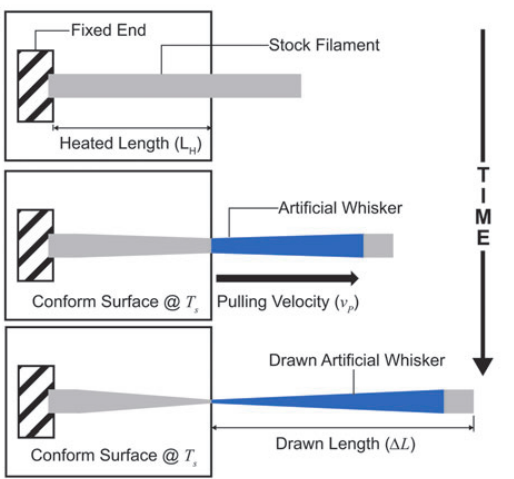

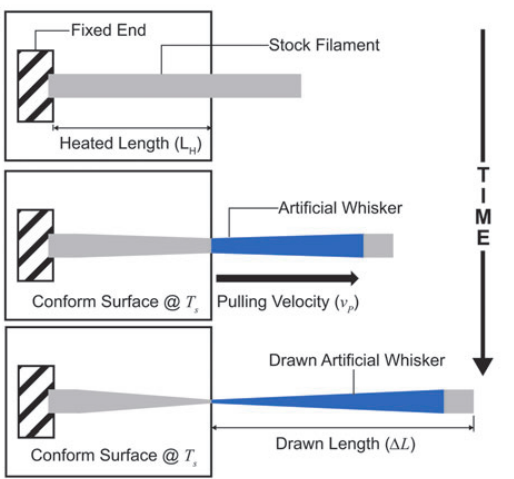

The image below shows how the shape of the filament develops over time. The heated length of the filament is brought to the plastic's glass transition temperature. Then the filament is pulled away from the oven by the drawing mechanism to create a taper.

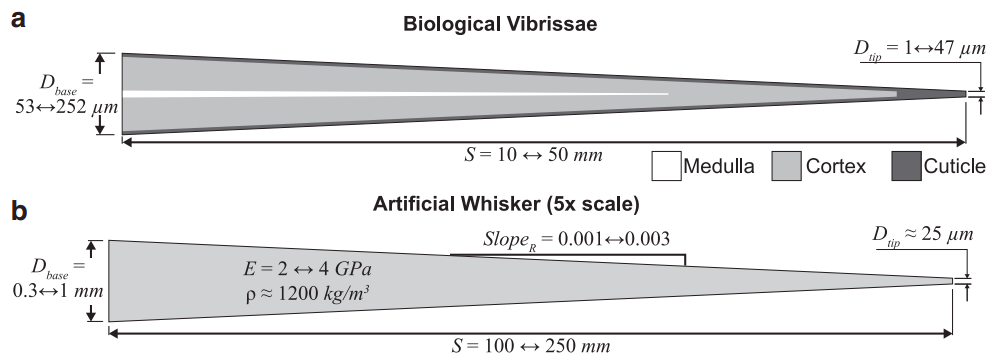

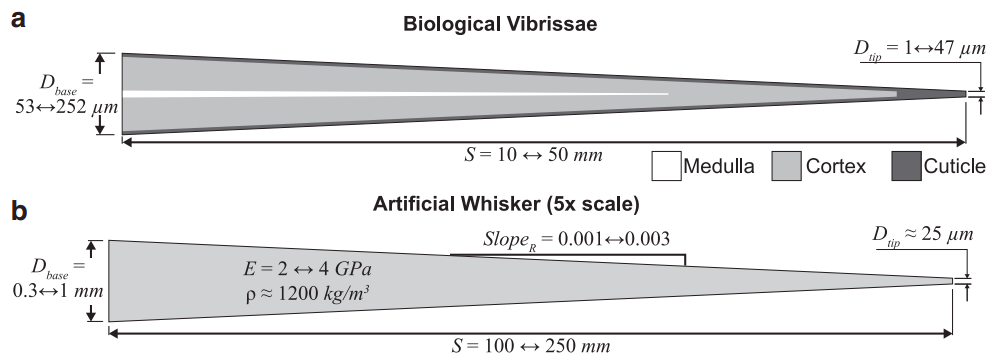

The artificial whisker geometric profile imitates that of a biological whisker at a 5x scale (see image below). These dimensions drove the design specifications for the drawing mechanism.

Design Specifications

Given the dimensions of an artificial whisker, the mechanism must:

- Include a linear actuator that can draw a 250 mm whisker in approx. 2 mins

- Achieve a velocity range of 0.01 mm/s - 10 mm/s

- Include velocity feedback control to regulate the whisker taper

- Have computer vision to inspect the whisker diameter in micrometers

Materials

- V-Slot® NEMA 17 Linear Actuator Bundle (Lead Screw), 400m stroke

- NEMA 17 Stepper Motor

- Tic 36v4 USB Multi-Interface High-Power Stepper Motor Controller

- Raspberry Pi 4

- Raspberry Pi High Quality Camera

- Monocular Max 300x Zoom C-Mount Glass Lens

- Microscope Camera Table Stand

- Adjustable LED Ring Light

- Electric Warming Tray with Adjustable Temperature Control

- 24V 4A 100W Power Supply Adapter

- Cable Assembly 2.1mm ID, 5.5mm OD Jack to Wire Leads

- FLIR ONE Gen 3 Thermal Camera Smart Phone Attachment

- Microscope Camera Calibration Slide Ruler

- Low-Friction Tape Made with Teflon

System Design

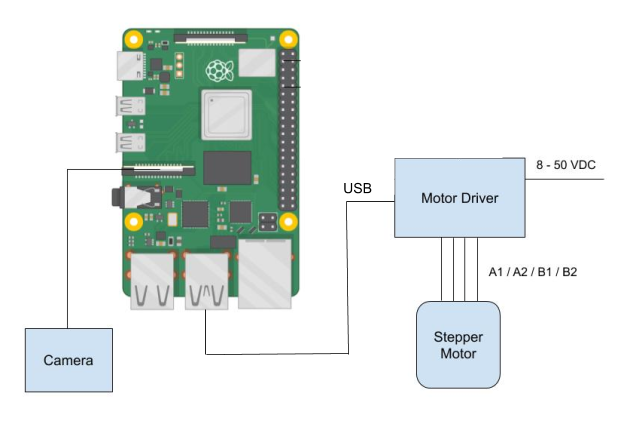

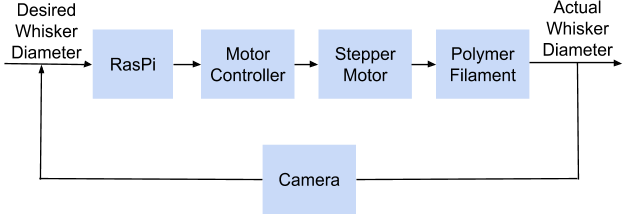

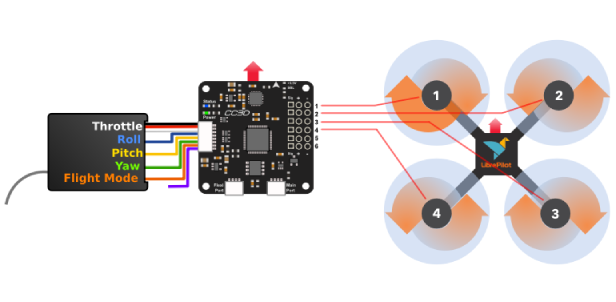

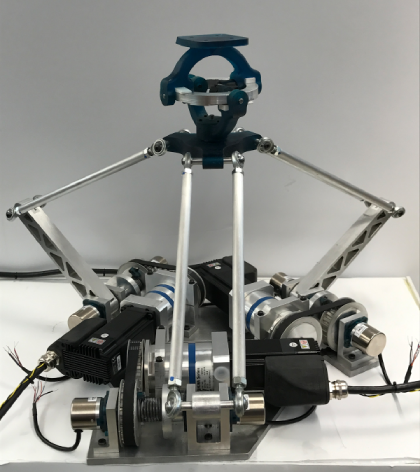

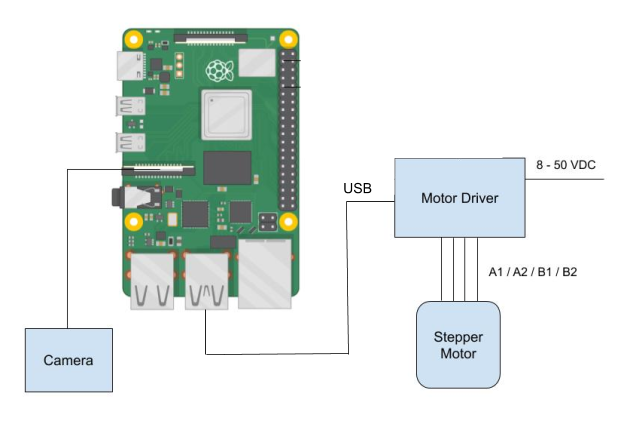

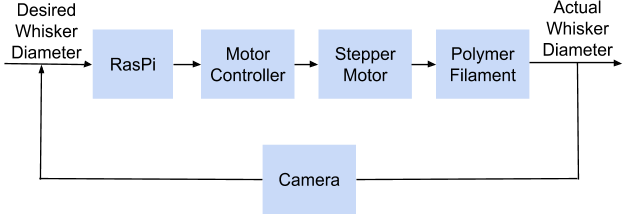

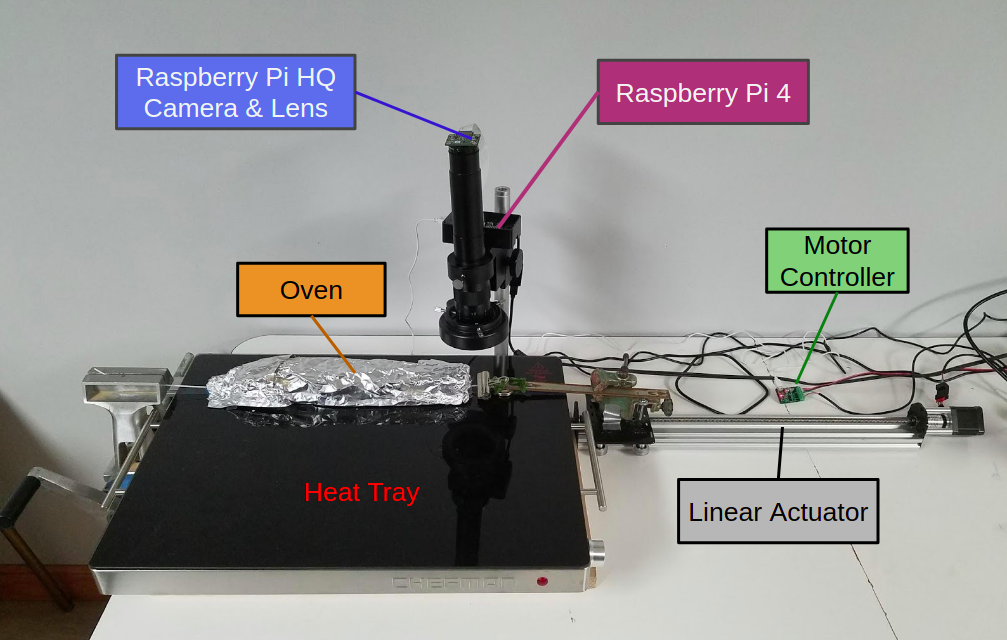

A block diagram of the system is depicted below. The Raspberry Pi controls the velocity of the lead screw linear actuator via the Tic motor controller. A High Quality Raspberry Pi camera is connected to the RasPi.

This setup allows the device to perform the following closed control loop. In order to acheive the proper whisker taper, the RasPi is provided a desired whisker diameter and sends the Tic a command to speed up or slow down the motor velocity based on the camera's examination of the whisker.

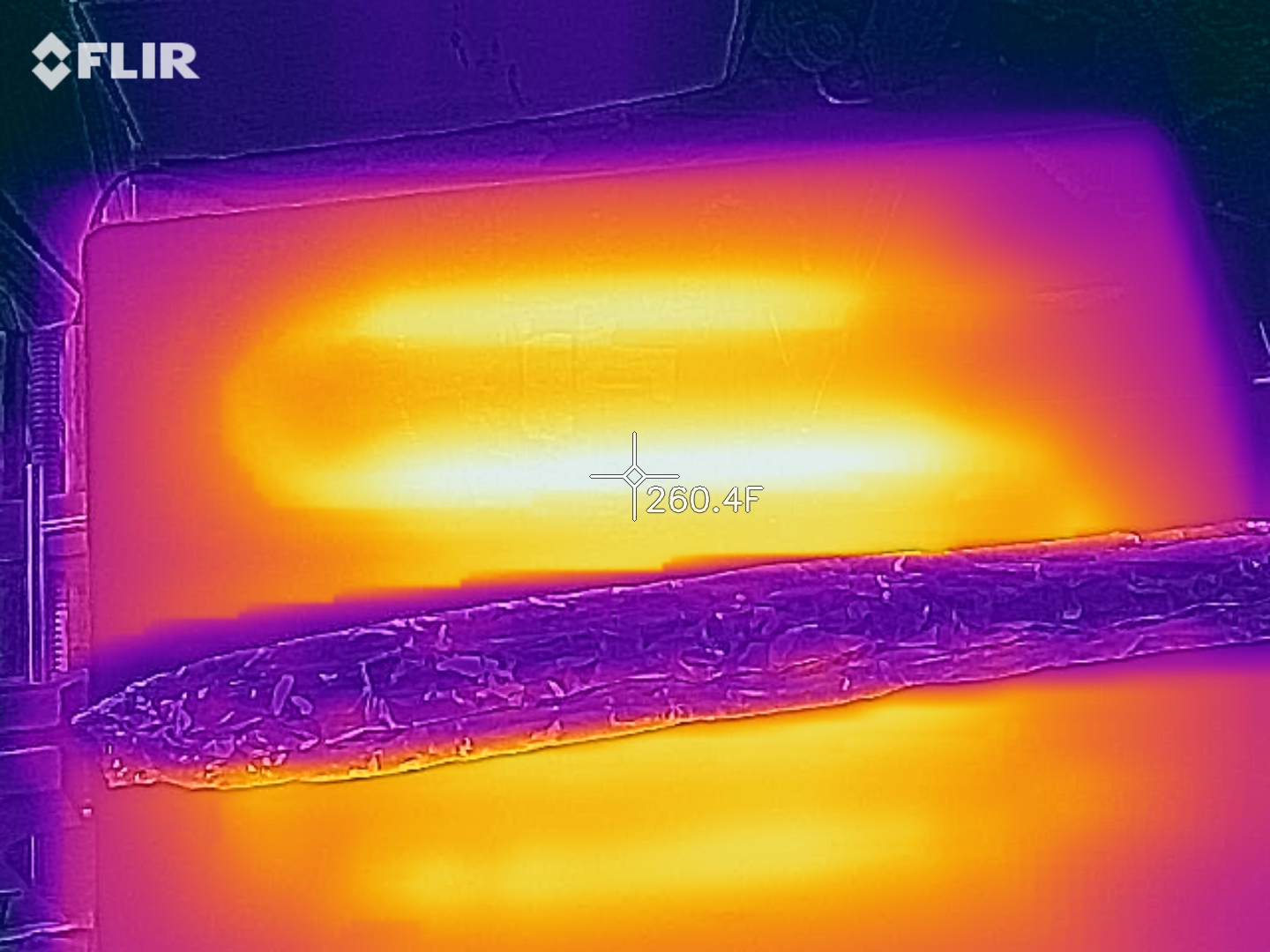

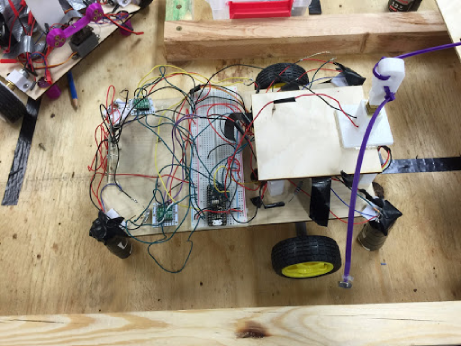

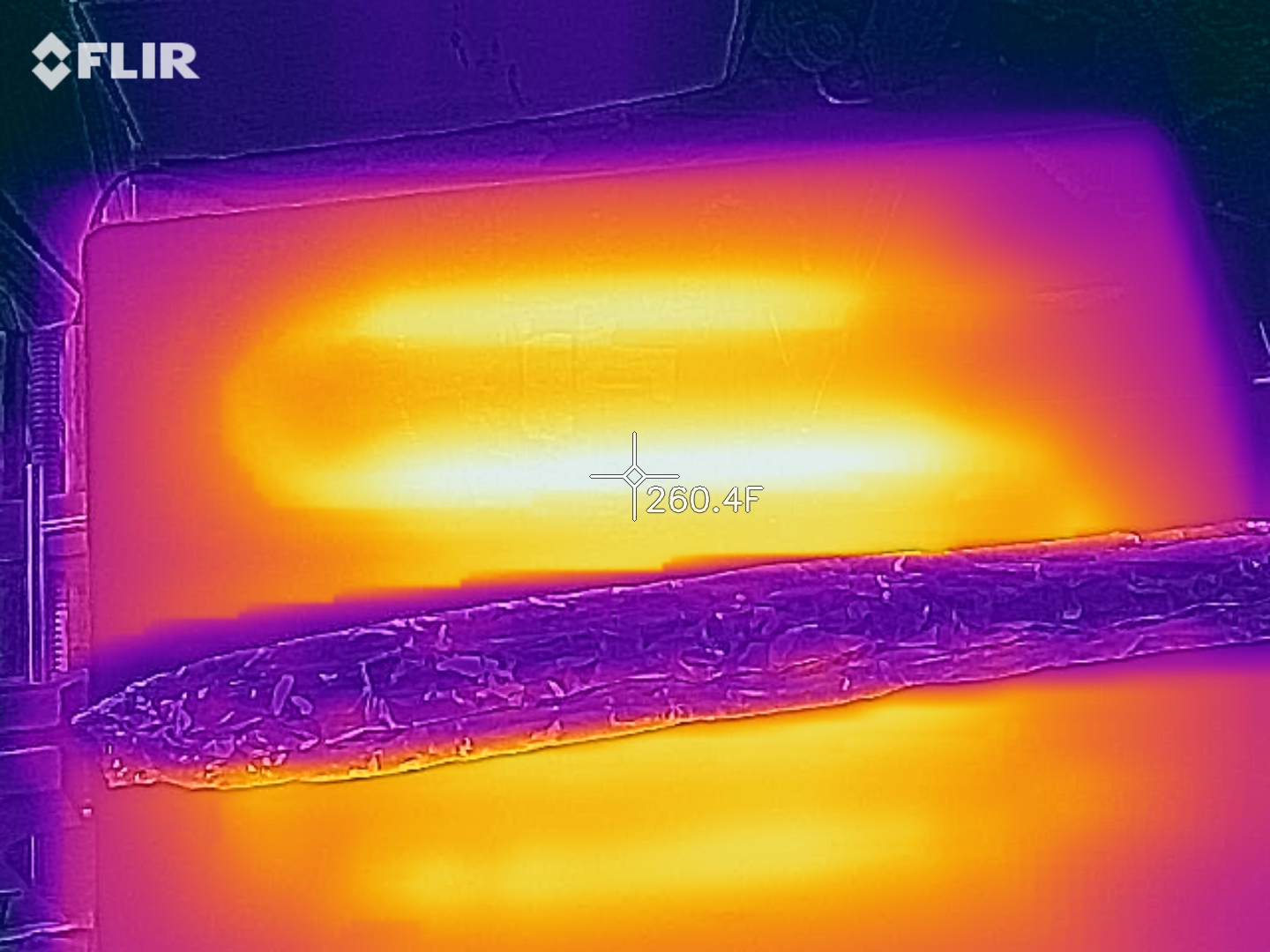

A 12" long, triple-layered hollow cylinder of heavy duty alumnium foil was created for the filament to travel through in order to heat up to its glass transition temperature. Low-friction tape made with Teflon was taped along the inside wall of the cylinder to allow the filament smoother movement. The heating element within the heat tray was found using a thermal camera smart phone attachment (see image below), and the aluminum foil cylinder was placed above and in parallel with one fold of the heating element.

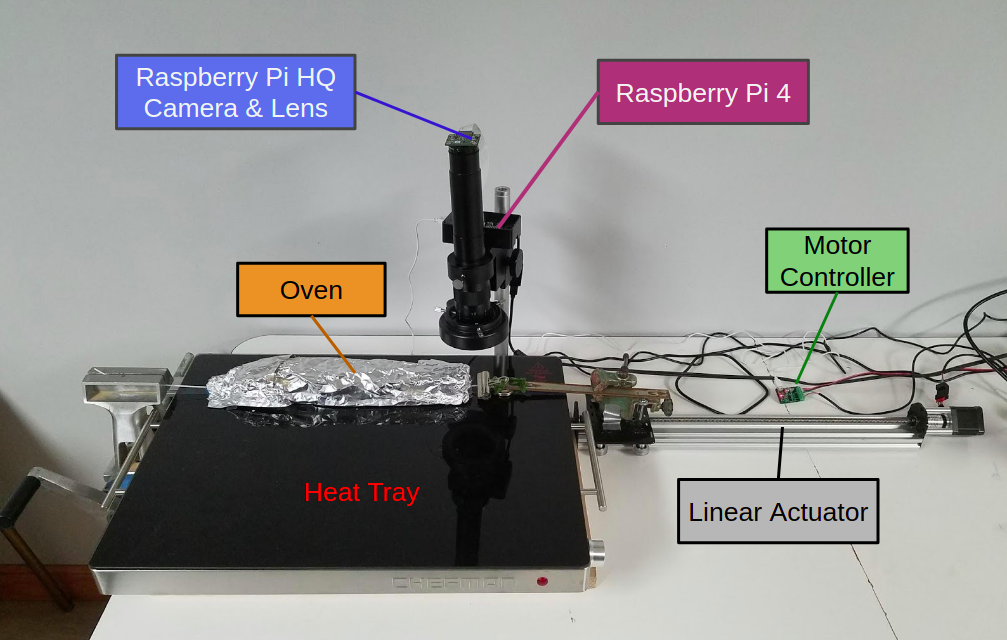

The finished setup looks like this:

Computer Vision

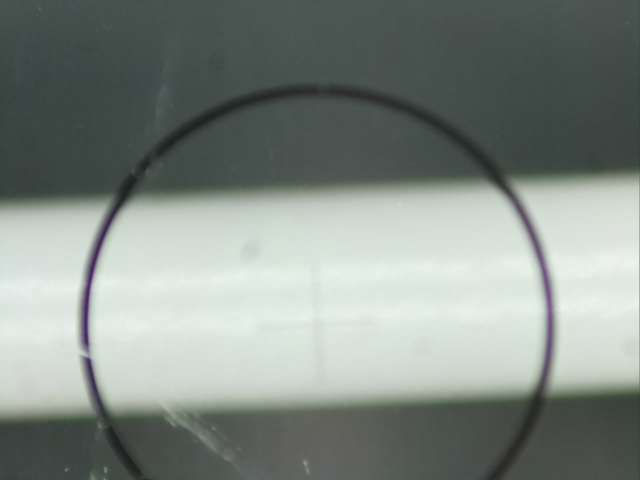

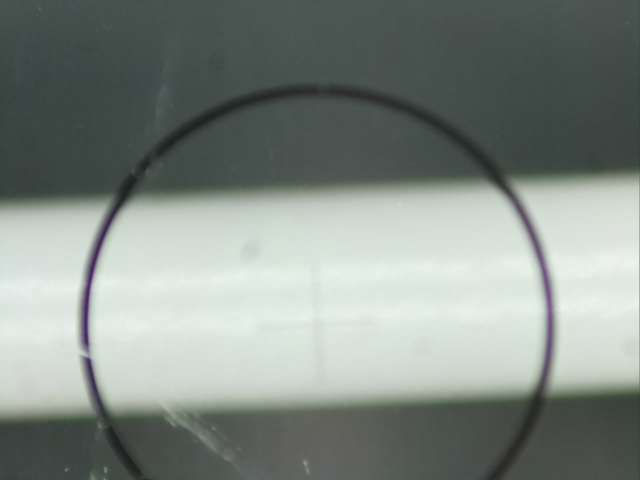

In order to accurately measure the whisker diameter, the camera and lens must be first focused on a calibration slide's 1mm x 1mm reticle while the slide is stacked on top of a sample of the plastic filament, as shown in the image below. The edges of the whisker need to be as focused as possible while the reticle is still visible, yet blurry.

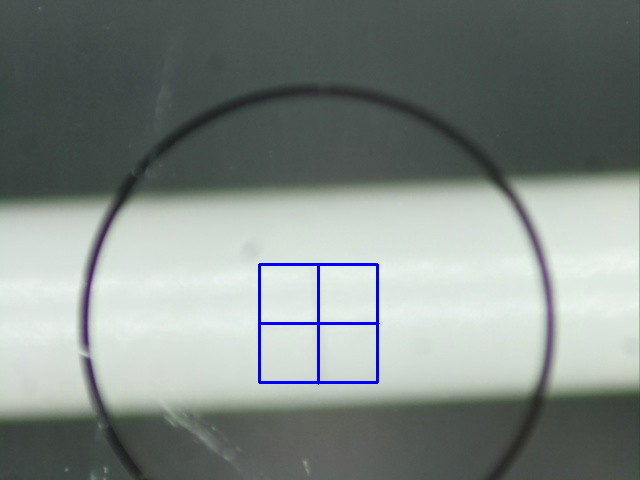

Next, in the script cam_calibration.cpp, the user drags and drops a rectangle around the reticle (displayed below), and the program calculates pixels/μm. The resulting number is saved to a text file where the whisker drawing program, whisker.cpp, can access this number when it is measuring the whisker diameter.

Whisker Drawing

Each run of the whisker drawing program takes approximately 3 minutes and is separated into two phases. The heating phase consists of feeding a length of 3D plastic filament through the oven, securing one end of the filament to the linear actuator and the other end to a vice attached to the table, and allowing the filament to heat up to its glass transition temperature for 2 minutes. Once the filament is done heating up, the user presses the Enter key to start the drawing phase. In this phase, the actuator pulls the filament according to a fixed velocity equation. The camera measures the whikser diameter directly outside the oven and adjusts the motor velocity proportionately to acheive the desired geometric whisker profile.